Installing a smart vehicle weighing system is not simply about choosing the right equipment; it is a comprehensive technical requirement. Investors must understand standards, configurations, and infrastructure conditions to ensure accuracy and transparency in weight control. By clearly understanding the weighing station types, the requirements for installing a smart vehicle weighing system, and the operational process, authorities, businesses, and transportation projects can reduce errors, minimize risks, and optimize long-term costs.

What is a smart vehicle weighing system and how does it differ from traditional weighing stations?

What is a smart vehicle weighing system?

A smart vehicle weighing system is a weight-measurement solution using load sensors, automatic license plate recognition (ALPR) cameras, and IoT to automate the weighing process. Weight indicators, vehicle images, weighing time and location, and operational reports are digitized and centrally managed. Therefore, installing a smart vehicle weighing system becomes a crucial step in reducing errors and increasing transparency for transportation, logistics, and industrial zone projects.

Comparison between smart vehicle weighing systems and traditional weighing stations

| Criteria | Smart vehicle weighing system | Traditional weighing station |

| Operating method | Automatic weighing, data recording, image capturing, license plate recognition, data storage and reporting on a centralized management system. | Dependent on manual operations: weighing, recording in logbooks, and fragmented data entry. |

| Accuracy & stability | High accuracy, minimal human influence; provides alerts when sensors or devices malfunction. | Prone to errors due to reading mistakes, handwriting, and inconsistent operations between shifts. |

| Data management | Digitized data, quick lookup, clear authorization levels, easy integration with traffic monitoring systems. | Dispersed data, difficult to compile reports, hard to trace information during inspections. |

| Monitoring & load control | Real-time monitoring, storing vehicle images and information, supporting transparent violation handling. | Mainly based on on-site observation and manual records, difficult to prove when disputes occur. |

| Operational personnel | Requires fewer personnel, focusing on supervision and data analysis. | Requires more personnel for weighing, recording, data entry, and reporting. |

| Scalability | Easy to expand weighing lanes, weighing points, and connect to the centralized management center. | Difficult to expand; each station operates almost independently. |

| Suitable model types | Smart transportation projects, expressways, industrial zones, ports, logistics facilities, large factories. | Small weighing points with simple management needs and low vehicle volume. |

Types and basic configurations of a smart vehicle weighing system

Static weighing

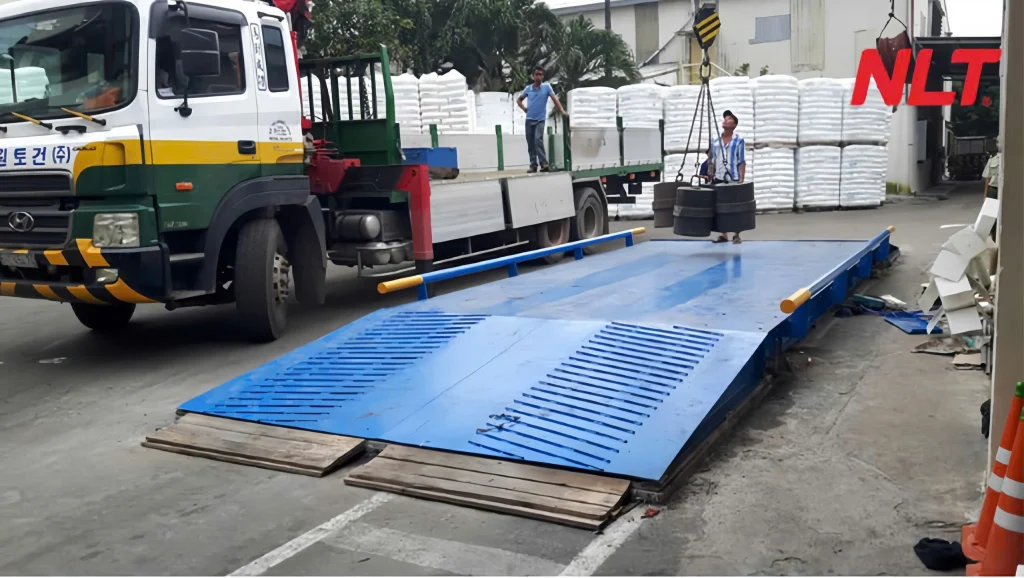

Static weighing is a system in which the vehicle stops completely on the weighing platform to measure the load. The basic configuration includes the weighing platform (pit-mounted or surface-mounted), loadcells, indicator–control cabinet, license plate capture camera, and data recording software.

When installing a smart vehicle weighing system using static weighing, the foundation must have strong load-bearing capacity, a flat surface, and minimal vibration or uneven settlement to keep measurement errors within the allowable range. Static weighing is suitable for factories, warehouses, industrial zones, ports, and material mines where vehicles can stop briefly. Its main advantages are high accuracy and easy calibration.

Dynamic weighing (WIM)

Dynamic weighing allows load measurement while the vehicle moves through the weighing zone at a defined speed without stopping. It is commonly used when installing a smart vehicle weighing system on expressways and national highways. The configuration typically includes WIM sensor strips embedded in the road surface, speed sensors, dedicated loadcells, a central controller, a license plate recognition camera, and real-time data processing software.

The installation road segment must be long enough, straight, structurally stable, and constructed to proper standards to minimize vibration, impact forces, and signal noise. Dynamic weighing is suitable for expressways, national highways, load control checkpoints and smart traffic projects with high traffic volume, helping prevent congestion and effectively detect overloaded vehicles.

Technical standards required when installing a smart vehicle weighing system

Calibration standards – accuracy – allowable error

Weighing equipment must comply with calibration standards related to accuracy, allowable error margins, and operational stability. Initial and periodic calibration is mandatory in all smart vehicle weighing system projects to ensure reliable load data for internal management and regulatory purposes.

Foundation and pavement requirements

The foundation is the decisive factor influencing accuracy when installing a smart vehicle weighing system. It must be load-bearing, flat, stable, and not prone to differential settlement over time. For static weighing, the structure must be standard concrete; for dynamic weighing (WIM), the road must be straight, sufficiently long, and well-constructed to limit vibration that causes measurement errors.

Signal transmission and data security standards

When installing a smart vehicle weighing system, the signal transmission from loadcells, WIM sensors, and cameras to the control cabinet and central system must be designed with anti-interference, lightning protection, and power backup to avoid sudden data loss. Weighing data, images, and license plate information must be encrypted, access-controlled, and backed up regularly to ensure data integrity and safety during retrieval and auditing.

Installation process for a smart vehicle weighing system

Site survey – location assessment

This is the most critical step when installing a smart vehicle weighing system. The engineering team evaluates vehicle volume, road conditions, available space for the weighing platform, control cabinet, cameras, and electrical–network infrastructure. This ensures the selected location maximizes accuracy without disrupting traffic or production.

Technical design – infrastructure preparation

Based on survey results, the engineering team prepares the technical design: type of weighing (static or WIM), equipment layout, foundation requirements, drainage systems, electrical lines, signal lines, and control room/pole placement. This stage includes foundation work, road surface treatment, and other preparations required for installing the smart vehicle weighing system.

Equipment installation – system integration

Once infrastructure is completed, the weighing equipment, sensors, loadcells, cameras, barriers (if needed), control cabinets, and network systems are installed according to technical drawings. At the same time, weighing management software, license plate recognition, data storage, and connections to the central monitoring system (if applicable) are configured, forming a fully integrated system from field to control room.

Calibration – handover – operational training

After installation, the system undergoes testing, adjustment, and calibration to verify accuracy and stability. Technical documents, manuals, and operator training are then provided. Staff are trained to use the software, retrieve reports, handle basic situations, and coordinate with technical teams for maintenance or calibration.

Practical benefits of applying a smart vehicle weighing system

Transparent and accurate load control

The smart vehicle weighing system automatically and consistently records load, license plate, timestamp, and vehicle images. Data can be retrieved instantly, reducing human errors and supporting transparent load management. This provides clear evidence when working with partners, customers, or regulatory authorities.

Reduced manpower, optimized operations

The system automates most weighing, recording, data entry, and reporting tasks. Operators can focus on supervision and data analysis, reducing labor costs, minimizing human dependency, and increasing capacity to handle large traffic volumes.

Fraud prevention – reduced loss costs

Because weighing data is linked to license plates, timestamps, and images and stored centrally, attempts to manipulate the weighing process become significantly more difficult. Businesses reduce product loss, minimize disputes over weight, and protect internal roads, weighing bridges, and surrounding infrastructure, resulting in lower repair and maintenance costs.

>> See now: Top 6 benefits of installing a smart truck weighing station from NLT Group

Common mistakes when installing a smart vehicle weighing system incorrectly

Incorrect foundation causing measurement errors

Foundation errors are the most common issue in smart vehicle weighing system installations. Even with standard-compliant equipment, an unstable foundation causes force distortion on the loadcell, resulting in inaccurate measurements. Fixing foundation issues is often far more expensive than constructing it properly from the beginning.

Equipment failing calibration requirements

Skipping calibration or using substandard equipment makes the smart vehicle weighing system unreliable. Errors exceeding allowable limits directly affect operations and may cause weighing results to be rejected by regulatory authorities. This is a major risk for businesses that frequently report load data.

Lack of cameras and synchronized monitoring system

This issue is common in low-budget smart vehicle weighing system projects, causing data gaps and lack of transparency. The system only works effectively when load data, images, license plates, timestamps, and route information are linked within a synchronized monitoring platform.

Are you looking for a contractor to install a smart vehicle weighing system according to international standards?

For transportation projects, industrial zones, ports, logistics centers, or construction-material plants, choosing the right consultant and installation unit for a smart vehicle weighing system determines the accuracy and durability of the entire system. NLT Group has supported many investors in designing, constructing, and integrating smart vehicle weighing stations according to high technical standards, meeting modern load-control requirements.

Design, construction and IoT integration capability in projects

NLT Group’s engineering team is well-versed in the installation process for smart vehicle weighing systems—from surveys and weighing type selection to equipment placement, foundation preparation, electrical lines, and signal routing. The system is designed with IoT integration, enabling connectivity to control centers, smart traffic monitoring systems, or internal management software, forming a complete solution rather than a standalone weighing station.

>> See more: Top 7 advantages of NLT Group’s smart truck weighing system

Projects implemented and technologies used by NLT Group

With extensive experience in installing smart vehicle weighing systems on major routes, industrial zones, and logistics enterprises, NLT Group understands the practical conditions in Vietnam. Technologies used include sensors, loadcells, license plate recognition cameras, data management software, and remote monitoring platforms, meeting requirements for accuracy, scalability, and infrastructure compatibility.

>> You may be interested in: NLT Group successfully deploys the 4.0 smart weighing station on national highways

Maintenance, calibration and advanced technical support

After installing the smart vehicle weighing system, NLT Group continues to support clients through maintenance packages, periodic inspections, and calibration according to technical recommendations. The technical team is ready to assist remotely or on-site whenever upgrades, expansions, or troubleshooting are needed. As a result, investors receive not only a complete system but also a reliable technical partner throughout the entire lifecycle of the weighing station.

If you need a technically compliant, stable smart vehicle weighing system tailored to your project’s operational requirements, NLT Group is ready to accompany you from the survey stage to actual operation. Contact us for configuration consultation, detailed quotations, and fast, accurate, transparent deployment for modern weighing station models.

Nam Long Technology Investment Group (NLT Group)

- Hotline: 0911 379 581 – 028 3535 5968.

- Email: kinhdoanh@nlt-group.com.

- Tax code: 0313339640.

- Address: 43T Ho Van Hue, Duc Nhuan Ward, Ho Chi Minh City.

Tiếng Việt

Tiếng Việt