Smart vehicle weighing system pricing is the process of determining costs based on technical configuration, deployment conditions, and the standards applied to each specific project. There is no single fixed price for all cases, because each system can differ in weighing technology, number of lanes, civil works requirements, and legal or regulatory demands. Without a clear understanding of how pricing is formed, investors can easily misinterpret quotations, which may directly affect project efficiency. The article below explains how smart vehicle weighing system pricing is structured and which key factors should be considered.

Overview of smart vehicle weighing systems

What is a smart vehicle weighing system? How is it different from traditional weigh stations?

A smart vehicle weighing system is a digital solution for monitoring vehicle loads. It automatically collects weighing data, images, and vehicle information, then processes and manages them centrally through software.

Unlike traditional weigh stations that operate in isolation and rely heavily on manual processes, smart vehicle weighing systems can apply multiple weighing methods. These include weigh in motion for monitoring loads while vehicles are moving, static weighing for inspection or enforcement, or a combination of both depending on management objectives and site conditions. As a result, data is recorded, stored, and utilized consistently on a single platform.

Core modules of the system

A standard smart vehicle weighing system typically includes the following integrated modules:

- WIM sensors or load cells to measure vehicle weight

- A central controller for data processing and synchronization

- ANPR cameras, overview cameras, and infrared cameras to capture images and license plates

- Triggering devices to synchronize weighing and image capture

- Servers, network equipment, and technical cabinets for data storage and transmission

- Operating software including dashboards, reports, analytics, and alerts

- Data transmission and security modules

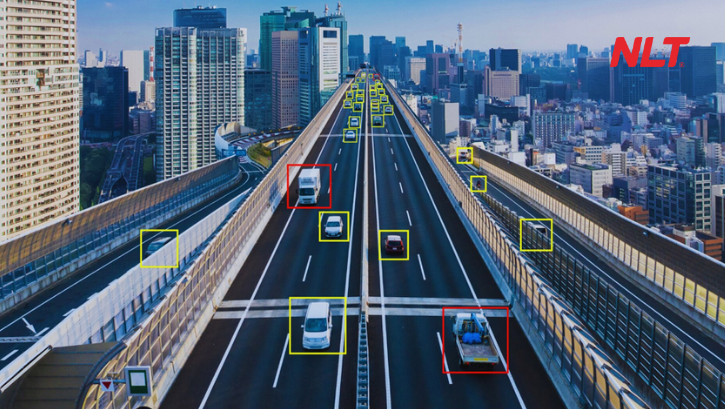

Digital transformation trends in vehicle load monitoring

With the development of smart transportation, vehicle load monitoring is increasingly connected to IoT, ITS, and traffic operation centers. AI is applied for license plate recognition, vehicle classification, and violation analysis. Digitalization reduces manpower requirements, improves data reliability, and expands management capabilities. This trend has a direct impact on smart vehicle weighing system pricing.

What factors affect smart vehicle weighing system pricing?

Weighing technology as a key pricing factor

The weighing technology selected is a fundamental factor in determining smart vehicle weighing system pricing. Depending on management goals and site conditions, systems may use dynamic weighing, static weighing, or combined solutions.

Each technology imposes different requirements for sensors, pavement structure, and accuracy levels, which directly affect system costs. The chosen technology also defines the technical and legal requirements that must be met during acceptance and operation.

Project scale and configuration

The number of lanes, vehicle speeds at the weighing point, and vehicle types directly influence the choice of weighing technology, sensor types, and equipment layout.

Higher daily traffic volumes require more cameras, stronger processing servers, and larger storage capacity. The choice of ANPR, infrared, or AI cameras, as well as cloud based or on premise storage and future scalability, also affects overall pricing.

Civil works and infrastructure integration

Construction costs depend heavily on existing road conditions and construction constraints. Activities such as road cutting, sensor installation, pavement restoration, and load bearing foundations often represent a significant portion of the total cost. Additional expenses may include power supply systems, cabling, fiber transmission, traffic safety equipment, and integration with existing ITS or traffic management centers.

Technical and legal standards

Systems can only be accepted when they comply with applicable technical and legal standards. Requirements based on OIML, national standards, and regulations from transport authorities directly influence equipment selection and system configuration. Projects that use weighing data as a legal basis for enforcement require higher accuracy and stricter verification, which increases system pricing accordingly.

Operating and maintenance costs (OPEX)

Operating costs include sensor maintenance, camera servicing, error calibration, and periodic verification in accordance with regulations. Service level agreements, response times, and warranty or maintenance packages should be defined from the outset. Accounting for operating expenses helps investors plan budgets throughout the system lifecycle.

Automation level and software capabilities

Requirements for real time dashboards, reporting, and violation alerts directly affect system pricing. The use of AI, data integration with other management systems, and user access control increase costs depending on the desired level of automation. Higher automation delivers greater data utilization efficiency but requires higher initial investment.

Reference pricing for smart vehicle weighing systems

Pricing by system type

Market pricing mainly varies by the selected weighing technology:

- High speed weigh in motion systems: have the highest investment cost due to high accuracy sensors and large data processing requirements

- Low speed weigh in motion systems: have medium investment levels and are suitable for fixed control points

- Static weigh stations: have lower equipment costs than WIM systems but require dedicated foundations and inspection procedures

- Multi technology weigh stations: involve higher investment due to the integration of multiple weighing methods

Pricing by configuration and project scale

Smart vehicle weighing system pricing is commonly structured by the number of lanes, such as one lane, two lanes, or four lanes. More lanes result in higher equipment, construction, and data processing costs.

Depending on needs, pricing can be provided as a full EPC package covering equipment, software, construction, and verification, or as separate modules such as cameras, load cells, WIM sensors, servers, and software. This approach allows investors to allocate budgets flexibly.

Total cost of ownership analysis (TCO)

Accurate pricing should consider the total cost of ownership, including initial capital investment and ongoing operating and maintenance expenses.

Future expansion and upgrade potential also affect long term costs. In the long run, smart vehicle weighing systems often deliver higher economic efficiency than traditional weigh stations by reducing manpower requirements and improving management effectiveness.

Standards and technical requirements affecting smart vehicle weighing system pricing

OIML standards – international standards for vehicle weighing

OIML is an international set of standards defining technical requirements for automatic vehicle weighing equipment. It specifies measurement criteria such as allowable error, operating speed range, and equipment durability to ensure reliable and accurate weighing results in line with international benchmarks. Compliance with OIML typically requires higher-quality equipment and sensors, which increases overall system costs.

>> Learn more: IoT-based smart vehicle weighing systems compliant with international standards

Vietnamese standards for vehicle load control stations

In Vietnam, vehicle weighing stations must comply with technical regulations and standards issued by regulatory authorities, covering weighing equipment, camera systems, data handling, and operating conditions. These requirements directly affect system configuration and the scope of items included in the quotation.

Among these, QCVN 66:2024/BGTVT is the national technical regulation specifying minimum requirements for vehicle load inspection stations, including weighing systems, surveillance cameras, weighing data, and design requirements for automated weighing stations.

Allowable error limits and calibration requirements

Permissible error limits determine the choice of weighing technology and sensor accuracy class. The lower the allowable error, the higher the cost of equipment, calibration, and periodic verification. This is a critical factor to consider when preparing the initial quotation.

Operational verification before handover

Before being put into operation, a smart vehicle weighing system must undergo verification and trial operation in accordance with regulations. Inspection steps, calibration, and completion of acceptance documentation must all be included in the quotation. Proper preparation helps avoid additional costs and delays in handover.

Survey – quotation – deployment process for smart vehicle weighing systems

Site survey process

An accurate smart vehicle weighing system quotation always begins with a thorough site survey and proper design. The survey assesses road conditions, power and network infrastructure, and traffic volume at the installation site. Survey results form the basis for selecting suitable weighing technology and define the scope of items included in the quotation.

Technical configuration and cost estimation

Based on survey data, the implementation unit develops a technical configuration aligned with management objectives. The smart vehicle weighing system quotation is prepared in detail by equipment, construction, and related services, ensuring realism and cost control.

Design, construction, and installation

This phase includes technical design, foundation construction, and installation of weighing equipment, cameras, and control cabinets. Proper construction in accordance with the design ensures accuracy and system durability, directly affecting long-term operation.

Software integration and system tuning

After installation, the system is integrated with operating software and connected to the management center. Technical parameters are fine-tuned to ensure synchronized weighing data, images, and reports. This is a critical step before official verification.

Verification, acceptance, and handover

The system is verified according to regulations prior to acceptance and handover. Verification results and technical documentation provide the legal basis for operation. Complete acceptance helps avoid operational risks.

Trial operation and training

Before official operation, the system undergoes trial runs to assess stability and real-world performance. The implementation unit also provides training for operators, ensuring correct and effective use from day one.

Benefits of investing in smart vehicle weighing systems

Optimized monitoring and reduced load fraud

The system enables automatic, continuous vehicle load monitoring with minimal human intervention, significantly reducing load fraud. This is a key advantage over traditional weighing stations.

Data integration and improved management efficiency

Weighing data, images, and vehicle information are centralized on a single platform. Integrated data supports faster monitoring, aggregation, and analysis, improving decision-making in traffic management.

24/7 operation without on-site personnel

Smart vehicle weighing systems can operate continuously without permanent staffing, reducing labor demands and minimizing human error while maintaining stable monitoring.

Reduced congestion and improved traffic safety

Vehicles do not need to stop for weighing, reducing congestion at control points and minimizing traffic conflicts. This contributes to improved traffic safety along the route.

Optimized long-term costs

Over the system lifecycle, smart vehicle weighing systems reduce operating, staffing, and enforcement costs. Management efficiency improves while long-term expenses are better controlled, which is why many projects prioritize investing in compliant systems from the outset.

Risks of choosing low-cost, non-compliant vehicle weighing systems

High error rates and failure to pass verification

Low-cost systems often fail to maintain stable accuracy in line with technical requirements. Errors exceeding allowable limits make the system ineligible for verification, rendering collected data invalid for official use.

Sensor failures and rising repair costs

Lower-quality sensors and components degrade quickly under real operating conditions. Frequent repairs and replacements lead to unplanned costs and cause operational downtime.

Data loss and inaccurate reports

Inadequate software and storage architectures increase the risk of data loss or inconsistent records. This directly affects aggregation and reporting, reducing overall management effectiveness.

Non-compliance with legal requirements

Systems that do not meet technical standards fail to comply with current legal requirements. When weighing data is used for management or enforcement, legal risks increase significantly and projects may fail to meet their original objectives.

Higher long-term operating costs

Lower upfront investment typically results in higher operating and maintenance costs over time. When evaluated across the system lifecycle, total costs can far exceed those of a compliant solution selected from the outset. This is the most significant risk of choosing a low-cost option.

>> Learn more: How accurate are NLT truck weighing stations?

Why NLT Group is selected for large-scale smart vehicle weighing projects

Integrated ecosystem of solutions, equipment, and software

NLT Group delivers a fully integrated smart weighing ecosystem covering hardware, software, and technical infrastructure. This end-to-end approach ensures stable operation and future scalability.

AI, IoT, and Cloud technologies across multiple platforms

NLT Group solutions leverage AI, IoT, and centralized data platforms to enhance monitoring and analytics. Multi-platform integration provides flexibility for various management models.

Proven capability in route deployment, weighing stations, and ITS

NLT Group has extensive experience deploying systems across different road types and weighing station models. Integrated ITS implementation reduces technical risks during real-world deployment.

Five-layer quality control process

Each project follows a five-layer quality control framework including technical design, equipment and materials, installation, integration and tuning, and trial operation. This process detects issues early at every stage, ensuring compliance from the start and enabling accurate system pricing.

Warranty, SLA, and long-term maintenance

NLT Group offers clear warranty and SLA packages with defined response and resolution times. Long-term maintenance services help sustain system performance throughout its lifecycle.

Capability profile and flagship projects

NLT Group maintains a comprehensive capability profile supported by flagship projects in smart transportation. This track record underpins investor confidence in large-scale, high-requirement projects.

>> Learn more: NLT Group – A leading provider of truck weighing station solutions in Vietnam

Smart vehicle weighing system pricing should be based on proven implementation capability and deep understanding of technical standards. With end-to-end experience from survey and design to construction and maintenance, NLT Group meets the technical and legal requirements of transportation infrastructure projects.

If you are seeking transparent pricing, optimized costs, and long-term operational reliability for a smart vehicle weighing system, contact NLT Group for a tailored configuration consultation.

Nam Long Technology Investment Group (NLT Group)

- Hotline: 0911 379 581

- Email: kinhdoanh@nlt-group.com

- MST: 0313339640

- Address: 43T Ho Van Hue, Duc Nhuan Ward, Ho Chi Minh City

Frequently asked questions about smart vehicle weighing system pricing

Is verification mandatory in smart vehicle weighing system pricing?

Yes. In smart vehicle weighing system pricing, verification costs are mandatory so the system can be accepted and legally put into operation in accordance with regulations.

How often is recalibration required to keep smart vehicle weighing system pricing accurate?

Recalibration intervals depend on the weighing technology and management requirements, and are typically performed periodically in line with verification regulations. Recalibration costs should be included in OPEX when preparing smart vehicle weighing system pricing.

What is the annual maintenance cost for a smart vehicle weighing system?

Maintenance costs depend on system scale, number of lanes, and the level of automation. In smart vehicle weighing system pricing, this is usually presented as an SLA package or a periodic maintenance contract.

How long does it take to deploy a smart vehicle weighing system?

Deployment time depends on existing infrastructure conditions and project scope. On average, a smart vehicle weighing system takes several weeks to a few months to complete, from site survey to acceptance.

Does smart vehicle weighing system pricing include multi-lane expansion?

Pricing may include expansion options or list them separately, depending on initial project requirements. For large-scale projects, expandability is often considered from the smart vehicle weighing system pricing stage.

Can the smart vehicle weighing system integrate with existing ITS, VMS, or cameras?

Yes. Smart vehicle weighing system pricing is typically designed with flexibility, allowing integration with existing ITS, VMS, or camera systems, provided technical requirements are met.

Tiếng Việt

Tiếng Việt