When it comes to inland waterway traffic safety, few people realize that the navigation buoy system, though seemingly simple floating structures, is actually the first and most critical link in ensuring vessels move along the correct channels. However, like any equipment operating continuously in harsh environments, buoys can be damaged. To prevent a minor defect from escalating into a serious incident, this article provides guidance on how to handle damaged navigation buoys in accordance with current technical procedures and regulations, ensuring effectiveness and safety for the entire channel system.

Overview of navigation buoys and incident handling principles

Common buoy types and installation locations

In inland waterway and maritime navigation marking systems, buoys are classified based on their function and deployment location. The most common types include:

- Channel marking buoys (left-hand buoys, right-hand buoys): used to mark the boundaries of the main navigation channel, helping vessels maintain the correct course.

- Danger warning buoys: indicate the location of submerged rocks, underwater structures, shallow river sections, or restricted areas.

- Mooring buoys and area boundary buoys: commonly used at ports, bathing areas, and aquaculture zones.

Each buoy type is strictly regulated in terms of color, shape, light signals (if applicable), and fixed installation coordinates according to designs approved by the competent authority. Incorrect installation locations or the use of improper buoy types can lead to navigational misunderstandings, compromise safety, and violate technical regulations.

Principles for handling damaged buoys in accordance with current legal regulations

Handling damaged buoys must not be done arbitrarily. According to the Inland Waterway Traffic Law, Circular No. 25/2019/TT-BGTVT, and technical guidelines issued by the Vietnam Inland Waterways Administration, the following principles must be observed:

- Timely detection – notification – handling: Any unit that discovers a damaged buoy must immediately report it to the waterway management authority or the relevant port authority.

- No unauthorized removal or relocation of buoys without permission or specific instructions from the competent authority.

- Priority for temporary remedial measures to ensure navigation safety while awaiting permanent repair or replacement.

- Repair or replacement must comply with the original technical documentation and Vietnamese technical standards for waterway navigation aids (QCVN 39:2011/BGTVT and equivalent regulations).

Any deviation in handling damaged buoys, even minor, may result in serious safety consequences and subsequent legal liability.

Common types of damage to inland waterway navigation buoys

Buoys drifting away from their designed positions

This is one of the most frequent incidents, especially after floods, tidal surges, or collisions with large vessels. When a buoy is no longer at its designed coordinates, the guidance signals provided to vessels become inaccurate, increasing the risk of vessels deviating from the channel, running aground, or colliding with obstacles. The causes typically include weakened mooring systems, corroded anchoring structures, or strong current forces. Even if the deviation is only a few meters, the buoy must be repositioned accurately, verified against digital charts or the original GPS coordinates to ensure precision.

Lights not operating or flashing at incorrect rhythms

Buoys equipped with lights are essential for nighttime navigation and operation in foggy or heavy rain conditions. If the light does not flash at the correct rhythm, whether too fast, too slow, or not illuminated at all, vessels will be unable to identify the buoy type and its function. Common causes include:

- Damaged control circuits

- Depleted batteries due to ineffective charging from solar panels

- LED lights deteriorated after prolonged operation

Non-operational or incorrectly operating lights are classified as serious faults and must be addressed within 24 hours of detection to ensure maritime safety.

Loss of positioning and GPS data transmission

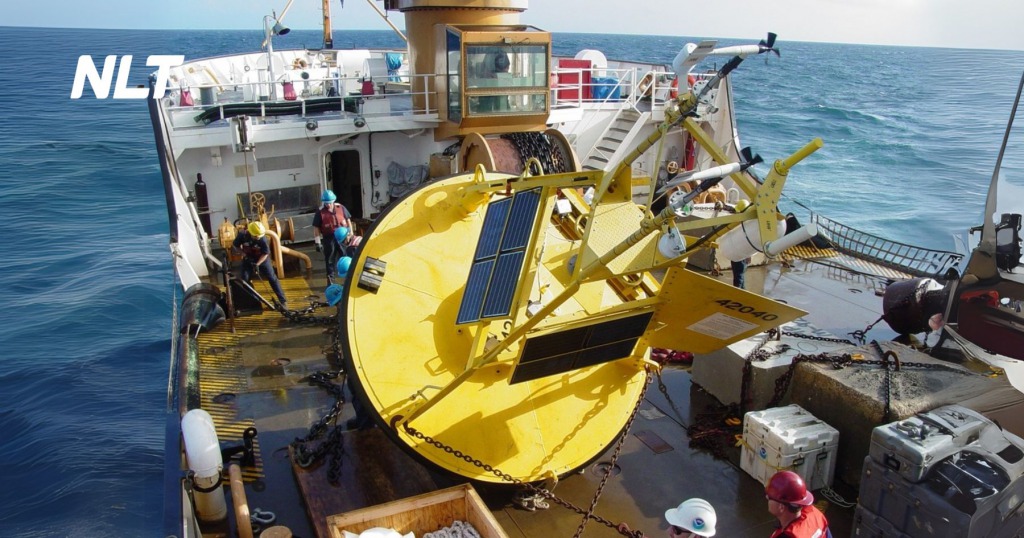

For modern buoys integrated with positioning and remote data transmission devices via LoRa, NB-IoT, or similar technologies, the loss of GPS signals or disconnection from monitoring systems indicates a malfunction. Possible causes include damaged GPS modules, antennas covered with marine growth or dislodged from their positions, or power supply failures affecting the GPS system. Loss of positioning renders the buoy invisible on digital maps, complicating management and inspection. Both hardware and software components must be checked to identify the root cause.

Leakage, cracked bodies, broken joints, or corrosion

Buoy bodies are typically made of HDPE plastic, composite materials, or galvanized metal. Despite their durability, prolonged exposure to saltwater, sunlight, and physical impacts can lead to:

- Cracks caused by collisions with sharp objects

- Corrosion at joints, lifting points, or steel rings

- Structural failure of light supports or protective covers

If not promptly addressed, water leakage can cause buoy imbalance, tilting, or partial submersion, resulting in incorrect signaling and loss of warning effectiveness.

Complete loss of warning capability in nighttime or foggy conditions

This is the most dangerous failure scenario and is often the result of multiple accumulated faults such as non-functional lights, battery failure, buoy tilting, or incorrect positioning. In low-visibility conditions, if a buoy cannot emit light signals or is not in its correct position, vessels lack essential navigational references, significantly increasing the risk of serious accidents. In such cases, emergency warnings must be activated, temporary notifications issued via VHF radio, auxiliary guard vessels or signals deployed, and immediate repair or replacement carried out.

>> See more: Detailed guidelines for inspecting and detecting inland waterway buoy faults

Standard procedure for handling damaged buoys in accordance with regulations

According to Circular No. 77/2014/TT-BGTVT issued by the Ministry of Transport, the handling of damaged buoys must comply with the maintenance procedure for inland waterway navigation aid systems, ensuring navigation safety and avoiding signal confusion for waterway vessels. The handling process includes the following main steps:

Step 1: Inspection and identification of damage status

Immediately after detecting signs of damage, displacement, or signal loss, the management or maintenance unit must conduct on-site inspections using methods such as direct observation, unmanned aerial devices if necessary, GPS measurements, and checks of the lighting system, batteries, and positioning equipment. The level of damage must be clearly classified as minor, moderate, or serious.

Step 2: Recording and preparation of on-site inspection minutes

Pursuant to Article 12 of Circular No. 77/2014/TT-BGTVT, all damage must be documented in an on-site inspection record, including the following contents:

- Route name and buoy identification code

- Type of incident and its impact on signals or positioning

- Images, coordinates, and time of detection

- Personnel involved and inspecting unit

This record serves as the basis for reporting to the competent authority and proposing handling measures.

Step 3: Notification to the competent management authority

If the incident exceeds the handling authority of the operating unit, for example buoys drifting off the route, complete signal loss, or impacts on the main navigation channel, it must be immediately reported to the regional Inland Waterway Sub-Department or the local Department of Transport. For routes under central management, the report must be submitted to the Vietnam Inland Waterways Administration.

Step 4: Implementation of temporary warnings to ensure traffic safety

While awaiting repair or replacement, the responsible unit must implement temporary warning measures, which may include:

- Installing warning signs, deploying auxiliary buoys, or assigning personnel to guide vessels

- Updating information on digital maps and remote monitoring systems, if available

- Issuing inland maritime notices regarding temporary channel conditions

This is a mandatory requirement emphasized in Article 16 of the Inland Waterway Traffic Law.

Step 5: Repair or replacement in compliance with technical standards

Depending on inspection results, buoys may be handled as follows:

- On-site repair for minor faults, such as replacing lights, cleaning solar panels, or tightening connections

- Replacement of components such as storage batteries, GPS devices, or LED lights

- Complete replacement if the buoy loses buoyancy or suffers severe damage

Any replacement must comply with the technical standards stipulated in QCVN 39:2011/BGTVT, including requirements on color, shape, light flashing frequency, load-bearing capacity, and material durability.

After completion, internal acceptance must be conducted, records updated, and completion reports submitted to the route managing authority.

Responsibilities and allocation in incident handling

Responsibilities of the route management authority

The route management authority, typically the regional Inland Waterway Sub-Department, the Department of Transport, or a specialized Project Management Board, plays a central role in maintaining, supervising, and handling the navigation aid system. Specific responsibilities include:

- Organizing periodic or ad hoc inspections during storms, floods, or upon reports from operating units

- Receiving, verifying, and processing incident information reported by relevant parties

- Assigning and directing maintenance units to address faults within the appropriate technical and legal scope

- Coordinating with port authorities, transport inspectors, and local authorities when necessary to ensure navigation safety

Responsibilities of maintenance contractors or operating units

Under maintenance contracts or service agreements, contractors are responsible for:

- Maintaining continuous operational status of buoys in accordance with technical regulations

- Promptly repairing common faults such as battery replacement, LED light replacement, correcting positional deviations, or cleaning energy equipment

- Timely reporting serious faults beyond their authority, and not undertaking repairs or replacements without approval from the managing authority

- Maintaining inspection and repair records, with acceptance minutes for each work item

Organizations failing to fulfill maintenance obligations may be subject to administrative penalties, contractual sanctions, or reductions in workload during evaluation periods.

When reporting to the Ministry of Transport or the Vietnam Inland Waterways Administration is required

Situations requiring reporting to the Ministry or the Administration include:

- Incidents causing complete loss of navigation signals for more than 6 hours, disrupting main transport routes

- Occurrence of damage to people or vessels due to navigation aid failures, whether suspected or confirmed

- Insufficient budget to handle incidents or the need to mobilize specialized equipment beyond local authority

- Systemic incidents affecting multiple navigation aid points along an entire route

Reports must be accompanied by inspection records, on-site images, fault descriptions, detection time, proposed handling measures, and the expected remediation schedule.

Guidelines for repairing and replacing equipment on buoys

Replacement of LED signal lights, batteries, and GPS devices

Signal lights, storage batteries, and positioning devices are components that are prone to damage due to weather conditions, material lifespan, or unstable input energy quality. When replacing these components, the following steps must be strictly followed:

- Switch off all power sources and remove protective covers using proper technical procedures.

- Use components that meet the exact specifications of the original design or the requirements set out in QCVN 39:2011/BGTVT, such as light color, flashing frequency, and LED durability.

- Check the output voltage of the solar panel and ensure that the replacement battery capacity is sufficient for a minimum of 5 days without sunlight.

- For positioning devices, activate and test the signal connection to ensure the module correctly transmits its position to the digital map via the internal software or the deployed monitoring platform.

Rectification of tilting, drifting, or loss of balance

Buoy tilting or drifting incidents typically result from broken mooring lines, worn connections, or abnormal changes in water currents. To rectify these issues, vessels must first approach and reposition the buoy close to its original location, then adjust the mooring system by replacing load-bearing lines, reinforcing anchoring rings, or using auxiliary buoys to stabilize the structure. If water ingress into the buoy body is detected and causes imbalance, the water must be removed using specialized equipment and the leakage point must be treated. After rebalancing, the buoy must be monitored for several hours to ensure that tilting or capsizing does not recur.

Repair of damaged shells and mechanical structures due to cracking, breakage, or corrosion

The handling of physical damage such as cracked buoy bodies, peeling protective layers, corroded lifting rings, or mounting bases must include the following actions:

- Clean the damaged area and apply composite resin or specialized waterproof materials for sealing and repair.

- Reweld broken metal parts and replace corroded bolts or anchor pipes, ensuring minimum strength in accordance with the original design specifications.

- Reapply the entire external protective coating using UV-resistant and salt-resistant materials to extend the service life of the equipment.

Shell repairs must ensure buoyancy and stability and must not alter the standard shape or color specifications of the buoy.

Reinspection of the mooring system and installation position against original coordinates

After technical repairs or repositioning have been completed, the following actions are required:

- Reposition the buoy using GPS to ensure a deviation of less than ±3 meters from the original coordinates stated in the design documentation.

- Check the integrity of the mooring system, fastening lines, and anchoring rings, and conduct load-bearing tests in accordance with the design standards.

- Update the buoy’s position and operational status in the monitoring software, navigation channel maps, and technical management records.

Reconfirmation of coordinates ensures that control systems and waterway vessels maintain accurate navigation guidance, especially in narrow channels, anchorage areas, or restricted zones.

Conclusion

Handling damaged navigation buoys is not merely a technical task but a mandatory process that must strictly comply with legal regulations, technical standards, and defined management responsibilities. Early detection, accurate classification, timely corrective action, and proper acceptance procedures help protect channel safety, prevent serious incidents, and ensure uninterrupted inland waterway transport operations. This task requires close coordination among operating units, maintenance contractors, and competent state management authorities.

FAQ

Can lights be replaced or buoys repaired without reporting?

No. According to Circular No. 77/2014/TT-BGTVT, all repair or replacement activities involving buoy components must be included in an approved maintenance plan or carried out under written instructions from the channel management authority. Unauthorized repairs, especially those altering technical features such as flashing frequency, color, or buoy position, may cause signal confusion and result in administrative penalties.

What is the time limit for handling a damaged buoy after it is detected?

This depends on the severity of the damage. For serious faults that directly affect channel safety, such as loss of light signal, positional displacement, or anchor drift, repairs must be carried out within 24 hours of detection. Minor defects may be addressed within 3–7 days, according to the periodic maintenance schedule.

Which defects require complete buoy replacement?

Buoy replacement is mandatory in cases where the buoy body loses buoyancy and cannot be restored, the structure is severely broken causing instability, the entire lighting and battery system is irreparable, or the buoy is damaged by major collisions, fire, explosion, or complete sinking. When replacing a buoy, the new one must match the original type, size, and technical standards.

Are private entities allowed to invest in and repair buoys themselves?

Private entities may invest in navigation buoys for port operations, inland wharves, or designated operational areas (e.g., anchorage zones, logistics projects). However, all installation, maintenance, and repair activities must be approved by the competent authority, typically the provincial Department of Transport or the Vietnam Inland Waterways Administration. Unauthorized implementation without permits or approved designs is not allowed.

Is there software available to manage buoy status remotely?

Yes. Several organizations have implemented buoy monitoring software integrated with GPS, LoRa, or NB-IoT technologies, such as Smart Buoy Management Systems (SBMS) or platforms provided by companies like NLT Group. These systems enable real-time remote monitoring of battery status, lighting, position, and incident alerts. This represents an inevitable trend in modern inland waterway navigation aid management.

Tiếng Việt

Tiếng Việt