In the context of increasingly complex traffic conditions and the growing need for strict vehicle load control, implementing smart vehicle weighing systems compliant with WIM (Weigh-In-Motion) standards has emerged as an advanced solution. This technology enables continuous and automated load monitoring 24/7 without disrupting traffic flow. So how does a full WIM-compliant system actually work? Let’s explore in the article below.

What is a WIM-compliant smart vehicle weighing system?

Weigh-In-Motion (WIM) concept

Weigh-In-Motion (WIM) is an advanced technology that allows vehicle loads to be measured while the vehicle is moving, without stopping as required by traditional static weighing methods. A smart weighing system integrates sensors installed beneath the road surface with supporting devices such as cameras and controllers to perform the following functions:

- Record axle loads, total vehicle weight, speed and license plate information

- Identify axle configuration and vehicle type in accordance with regulatory standards

- Compare actual loads with permitted limits and issue alerts when overload violations occur

By measuring loads while vehicles are in motion, the deployment of WIM-compliant smart weighing systems allows traffic authorities to maintain smooth traffic flow while enforcing load control more effectively.

Basic configuration of a WIM-compliant smart weighing system

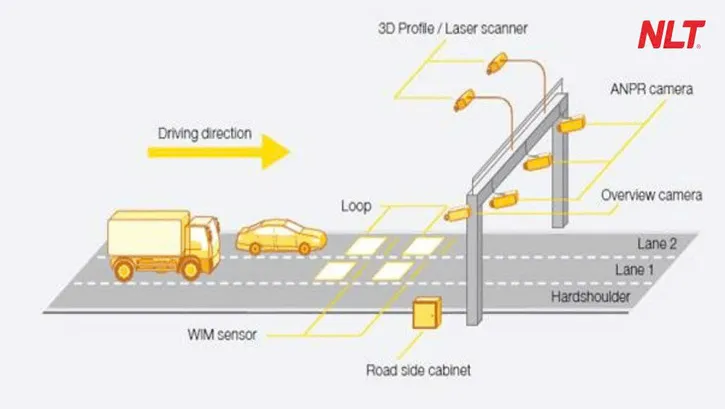

A typical WIM smart weighing system implementation includes:

- WIM sensors beneath the road surface or weighing slab: load sensors, speed sensors and axle detection sensors

- Camera system for license plate recognition: plate recognition cameras and overview cameras for verification and dispute handling

- Control cabinet and central processing unit: WIM processors for real-time load calculation, PLC or IPC controllers interfacing with sensors and software

- Smart weighing software and management platform: on-site operating interface, dashboards, online reporting, IoT integration, AI and digital mapping

- Supporting infrastructure: foundations, reinforced concrete beams, guide lanes, operation buildings, network and power systems, and site security cameras

Operating principle

Once a WIM smart vehicle weighing system is implemented, the operational process follows a continuous sequence:

- Vehicles pass through the sensor zone and the system measures loads in real time

- Cameras capture license plates and full vehicle images

- The processing unit standardizes data according to metrological standards

- Software compares measured loads against legal limits and automatically issues overload alerts

- Data is stored and transmitted to the central control center

Because loads are measured while vehicles are moving, WIM systems reduce the need for stopping vehicles, minimize congestion and still provide legally valid data when required.

Application categories

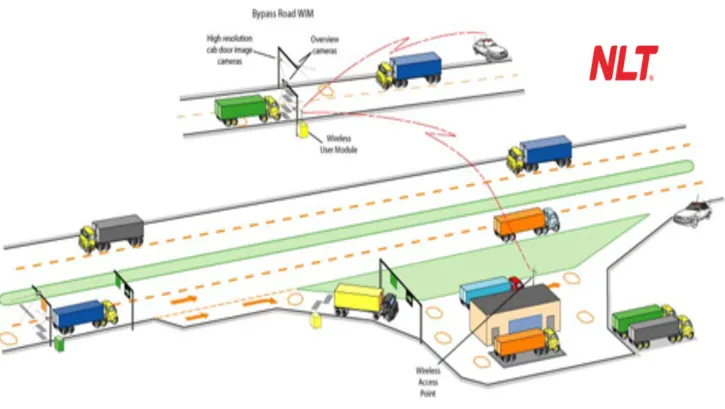

- Monitoring WIM: installed along roadways to rapidly screen all vehicles and automatically detect suspected overloads, then direct them to static weighing stations for further inspection

- Enforcement WIM: high-accuracy systems meeting state metrology standards, used as a legal basis for direct penalties or automated enforcement

- Enterprise management WIM: applied in factories, mines, batching plants, ports and logistics hubs to control inbound and outbound loads, reconcile invoices, optimize payloads and reduce transport costs

Why implement WIM-compliant smart vehicle weighing systems?

Continuous load control with reduced reliance on manpower

With WIM-compliant smart weighing systems, the entire process of measurement, data recording and storage is fully automated and operates 24/7 without the need for constant on-site personnel. For infrastructure owners, industrial zones and transport enterprises, this delivers clear benefits:

- Reduced staffing costs for night shifts, holidays and peak periods

- Lower dependency on manual operations and reduced human error

- Minimized conflicts of interest and misconduct during weighing and violation handling

Reduced congestion and improved road efficiency

Compared with traditional weigh stations, WIM smart weighing systems:

- Minimize vehicle stopping and long queues at weighing points

- Optimize traffic flow, especially on expressways, national highways, industrial zone entrances and ports

- Enable flexible lane management where compliant vehicles proceed directly while suspected overloaded vehicles are diverted for detailed static weighing

By implementing WIM-compliant smart weighing systems, investors and road authorities can significantly reduce congestion at weighing points without creating new traffic bottlenecks, while still maintaining strict load control.

Data transparency for enforcement and transport management

A major advantage of WIM-compliant smart weighing systems is comprehensive data storage and retrieval:

- Complete weighing records including license plate, vehicle type, axle configuration, timestamp, route, axle loads and total load, plus full vehicle images

- Encrypted data storage synchronized with centralized management platforms

- Seamless integration with digital traffic infrastructure systems, AI camera networks and fleet management platforms to build a comprehensive transport data ecosystem

For regulatory authorities, this enables transparent enforcement supported by verifiable evidence and reduced disputes. For enterprises, weighing data provides a solid basis for invoice reconciliation, route optimization, load planning, transport cost control and performance evaluation by route or transport partner.

>> See more: Top 6 benefits of installing smart truck weighing stations by NLT Group

Lợi thế khi chọn NLT Group thi công hệ thống cân xe thông minh chuẩn WIM

Năng lực kỹ thuật và kinh nghiệm triển khai tại Việt Nam

Advantages of choosing NLT Group to implement WIM-compliant smart vehicle weighing systems

Technical capability and implementation experience in Vietnam

NLT Group is a specialist in smart transportation systems, with extensive experience deploying Smart Vehicle Weighing 4.0 stations on key national highways. Our full delivery chain includes survey, design, construction, integration and maintenance.

- Proven expertise in integrating WIM sensors, cameras, barriers, traffic signals and warning systems into a unified platform

- In-depth understanding of legal regulations on vehicle loads, metrology standards and data connectivity requirements with authorities

- Experience deploying weighing systems connected to digital traffic infrastructure management platforms and other ITS solutions developed by NLT Group, forming a fully integrated solution suite

End-to-end solutions from hardware to management software

When implementing WIM-compliant smart weighing systems, NLT Group delivers more than equipment—we provide a true end-to-end solution:

- Consulting on standardized weighing procedures, traffic flow layouts and optimal installation locations

- Selecting appropriate configurations for sensors, cameras, control cabinets and supporting infrastructure

- Delivering Smart Weighing 4.0 software with on-site operating screens, user-friendly interfaces, online dashboards for investors and route managers, operations control rooms, load reports by route, time frame and vehicle group, and integration with IoT, AI and digital maps for 24/7 remote monitoring

Optimized investment and operating costs with robust warranty and maintenance

With experience across numerous smart weighing projects, NLT Group is able to:

- Advise on cost-effective combinations of WIM, static scales, cameras and infrastructure aligned with budget constraints

- Propose phased investment roadmaps that prioritize essential components and allow future expansion as demand grows

- Establish maintenance processes to ensure stable operation, extend equipment lifespan and minimize unexpected repair costs

>> See more: Top 7 advantages of NLT Group’s smart truck weighing systems

NLT Group’s process for implementing WIM-compliant smart vehicle weighing systems

Survey and solution consulting

- Assess site conditions, traffic volume and truck characteristics

- Analyze load management challenges and regulatory requirements

- Propose optimal WIM system solutions including lane count, station location, WIM model and supporting infrastructure

Technical design and construction planning

- Develop technical drawings for WIM sensors, foundations, weighing beams and control cabinets

- Design connection layouts for cameras, barriers, traffic lights, networks and power supply

- Prepare construction plans, schedules for each work item and night-time or traffic diversion plans to minimize disruption

Installation and construction

- Build foundations, drainage systems, weighing beams and technical trenches

- Install sensors, load cells, control cabinets, barriers, cameras and signage

- Ensure compliance with vibration resistance, settlement prevention and waterproofing standards in line with current technical and metrology regulations

Software integration and system connectivity

- Optimize software configurations and establish communication with sensors, cameras and management systems

- Integrate with traffic management platforms, fleet management systems and ERP/BI systems where required

- Finalize overload alert scenarios, reporting configurations and user access control

Calibration, validation and acceptance

- Conduct calibration and verification in accordance with regulations

- Perform test runs with various load scenarios, vehicle types and speeds

- Complete documentation, acceptance records and handover to the investor

Training and operational support

- Provide on-site training for station operators, technical teams and data management staff

- Supply user manuals and basic troubleshooting procedures

- Establish 24/7 technical support channels and periodic maintenance plans to ensure long-term, stable operation of the smart weighing system

This comprehensive approach enables NLT Group to deliver WIM-compliant smart vehicle weighing systems that are accurate, reliable and scalable for long-term traffic and transport management needs.

Application models of WIM-compliant smart vehicle weighing systems implemented by NLT Group

Application models of WIM-compliant smart vehicle weighing systems implemented by NLT Group

At load control stations on national highways and expressways, NLT Group implements smart vehicle weighing systems using a modern monitoring model that combines high-speed WIM weighing with static scales. This solution enables the detection and separation of suspected overloaded vehicles directly within the traffic flow, thereby reducing the number of vehicles required to stop for inspection and minimizing congestion at weighing stations.

Data from weighing sensors, AI cameras and license plate recognition systems is transmitted directly to the operations center, forming a transparent and accurate inspection process. This model is particularly suitable for traffic management authorities that require continuous 24/7 operation and large-scale violation handling.

Smart vehicle weighing systems for industrial zones, ports and logistics hubs

For areas with high transport volumes such as industrial zones, ports and logistics centers, NLT Group provides solutions that optimize the entire inbound and outbound cargo handling process. In these environments, implementing smart vehicle weighing systems enables load control directly at entry and exit gates, reduces losses and shortens processing time.

The system is synchronized with warehouse management software, ERP or OMS platforms, supporting vehicle identification via RFID cards, QR codes or dispatch orders. The load inspection process is fully automated, reducing manual intervention, eliminating errors and ensuring seamless data flow from gate entry to loading and delivery areas.

Smart vehicle weighing solutions for material mines, batching plants and manufacturing facilities

In extraction and manufacturing environments where strict control of raw material and finished product volumes is required, NLT Group deploys smart weighing systems with fully automated measurement, recording and reconciliation processes.

Weight data is linked to each trip and delivery note, helping enterprises minimize losses, shorten loading and unloading time and improve operational efficiency. Full data digitization also enables factories and material mines to manage output and balance production plans in real time.

By implementing WIM-compliant smart vehicle weighing systems, enterprises can standardize inbound and outbound procedures and eliminate dependence on manual weighing.

Implementing smart vehicle weighing systems not only enables more accurate and transparent load control, but also optimizes operations, reduces labor requirements, minimizes errors and ensures compliance with legal regulations. Selecting the right solution and a reputable contractor is critical to achieving effective investment outcomes and long-term system stability.

If you are an investor in traffic infrastructure, industrial zones, ports, material mines or manufacturing facilities and are seeking a WIM-compliant smart vehicle weighing solution, NLT Group is ready to support you from problem assessment to real-world implementation.

Nam Long Technology Investment Group (NLT Group)

- Hotline: 0911 379 581

- Email: kinhdoanh@nlt-group.com

- TIN: 0313339640

- Address: 43T Ho Van Hue Street, Duc Nhuan Ward, Ho Chi Minh City

Tiếng Việt

Tiếng Việt