NLT Group’s Smart Vehicle Weighing 4.0 solution helps minimize overloaded vehicles on the road. With a fully automated weighing and vehicle monitoring system, road infrastructure is optimally protected with extremely cost-effective and efficient investment, without affecting traffic flow.

The system operates with vehicle position sensors, barriers, card readers, etc., combined with surveillance cameras to create a transparent vehicle weighing system that prevents fraud and runs fully automatically. With remote monitoring and control capabilities, image reports captured by cameras and the data linked with accounting software, business management, and parking management systems enable a closed-loop management system that is optimized for enterprises.

Key features of NLT Group’s smart vehicle weighing system

NLT Group’s smart vehicle weighing system will provide 24/24 monitoring of vehicles travelling across the city, with a focus on heavy trucks, container trucks, construction material carriers, mineral transport vehicles, etc., which pose risks to transport infrastructure and road traffic safety. The product integrates smart features that deliver outstanding effectiveness in traffic management, including:

- Easy and fast installation on key transport corridors

- Addresses all current limitations (manual control and enforcement) of portable scales and mobile weighing vehicles

- Accurate, simple, and fast vehicle weighing in all weather conditions with the most cost-effective operating expenses

- Integrates a dedicated AI license plate recognition camera system developed by NLT Group with high accuracy and fast recognition time, providing 24/24 monitoring of vehicles travelling across the city

- Enables easy monitoring and automated enforcement with image evidence and overload data stored in the system database

- Optimizes all workflows and procedures for cargo weighing

- Allows centralized management of weighing stations on the Mobile App/ Website

- Retrieves all types of station reports and detailed information for each weighing session

==> See more: Smart transportation

Outstanding advantages of the smart vehicle weighing system

High accuracy

Under ideal conditions (laboratory conditions), the sensor system delivers an error rate of under 2%. This result confirms that quartz sensors are fully suitable for high-accuracy WIM measurements and can be used for applications such as enforcement and overweight toll collection.

Stability

The system uses highly stable quartz sensors. The measurement performance of quartz sensors remains very stable throughout the lifecycle of the WIM system, meaning frequent calibration or maintenance is not required. This is important and valuable in reducing maintenance costs and minimizing traffic disruption if the weighing system needs servicing.

Not temperature-dependent

Quartz WIM sensors are not temperature-dependent (error is only 0.05%/10C). This is very important to the performance of the entire WIM system, especially for countries with seasonal climate and environmental changes like Vietnam.

Customizable to road settlement

Quartz WIM sensors are installed on the road surface, which must be free of unevenness or speed bumps. Milling and paving an asphalt layer over the top surface of the sensor allows the WIM sensor to be installed with an allowable road settlement of 0÷10mm.

Easy installation

Based on the experience of NLT’s WIM weigh-in-motion engineers and experts, installing road-embedded sensors will not significantly affect traffic flow on the route.

No impact on the road surface

At the installation location, if the road surface meets the standard thickness of over 60mm, sensor installation will not affect road surface quality.

Automatic overload alerts

Overloaded vehicle information is immediately displayed on the system software’s operating screen.

Independent control

Integrated control with toll collection

Patrol units and competent authorities (Department Inspectorate, Traffic Police) can use the weighing system software anywhere as long as they are connected to the central server to receive overload alerts.

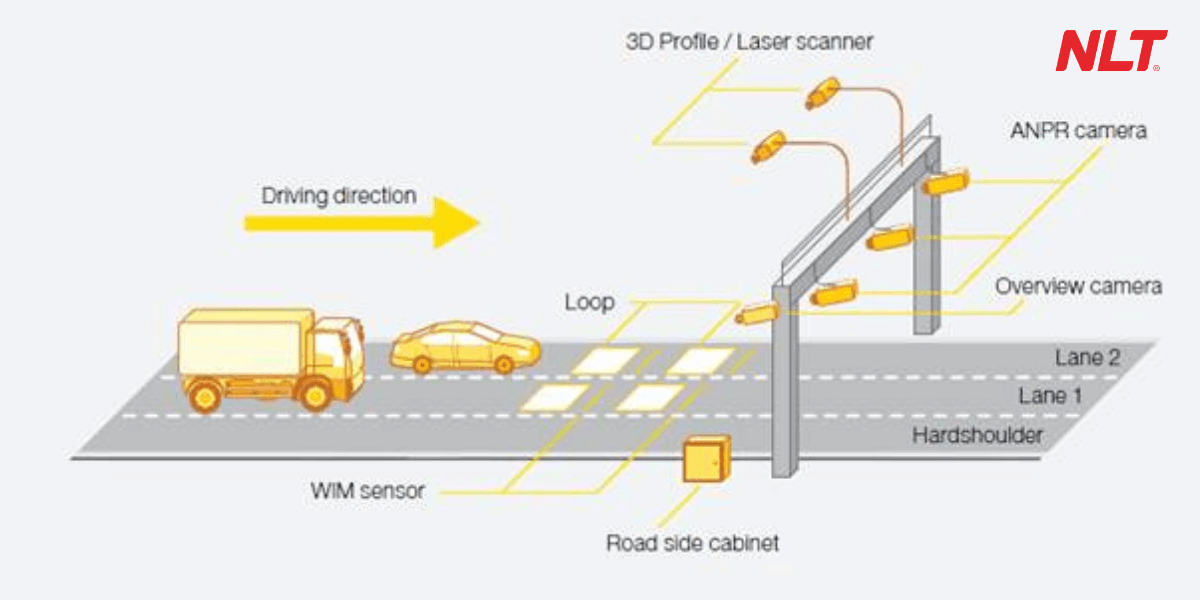

Diagram of the smart vehicle weighing system

Hardware:

- Load sensors: determine axle loads, gross vehicle weight, as well as other related information of vehicles passing through the station.

- Inductive loops: detect vehicles passing through the station.

- Control cabinet: Collect all relevant information about vehicles passing through the weighing station from load sensors, inductive loops and cameras. Calculate and determine whether a vehicle is overloaded and output the information to the warning display. Transfer all information to the Server for storage.

- Server: stores the weighing station’s data.

- Control station: located about 300–500 meters away from the weighing station, accesses data of vehicles passing through the station via the Internet or 3G. If an overloaded vehicle is detected, the competent authorities will be notified for appropriate handling.

- Control center: Store, manage and monitor information from all weighing stations remotely.

Software:

- Simple interface, easy to monitor and operate

- 24/7 remote monitoring of weighing stations

- Supports multiple monitoring methods across various devices

- Instantly displays overloaded vehicle information on the software and sends SMS/email to competent authorities

- Provides detailed statistics on vehicle load monitoring down to each axle, with images and intuitive charts

Operating principle of the smart vehicle weighing system

When a vehicle enters the weighing platform, the monitoring software will automatically detect the vehicle on the scale and activate automatic license plate scanning to identify vehicle information. The software will retrieve weighing data from the indicator and store it in the database for cross-checking with the weighing station management system at each site. Managers will receive reports from both software systems for reconciliation, helping minimize loss and fraud to the greatest extent possible.

Some products within the solution

NLT Group’s camera technical cabinet

- Outdoor powder-coated sheet steel cabinet, IP54, 1.5 mm thick, double-layer steel enclosure with thermal insulation between the two layers.

- Dimensions: D700xR500xH300mm

- 3 MCB Schneider 2P 32A

- RCBO 1P+N 32A

- 2 regulated switching power supplies 24VDC 400W, Sungho terminal block 220V 30A 10P

- POE power supply

- Cabinet lighting lamp

- 2 cabinet fans

- Thermostat and controller for the cabinet exhaust fan, switching device

- 3 network surge protection devices

- Grounding bar

- Camera Management: Allows users to monitor and control multiple cameras from one place.

- Anomaly Alerts: Provides notifications when motion is detected or when incidents occur.

- Remote Control: Can be managed via a mobile app or computer.

- Security Features: Supports security measures such as video encryption and access protection.

NLT Group’s weighing technical cabinet

Weighing cabinet equipment details

- MCB 2P 32A

- RCBO 1P+N 32A

- 5 MCB 2P 6A 6kA

- 9 MCB 1P 6A 6kA

- 2 regulated switching power supplies 24VDC 400W

- 5VDC 30W power supply

- 2 single-phase isolation transformers 220V to 24V 150VA (6A)

- Surge protective device

- Sensors

- 5 intermediate relays

- 2 cabinet fans

- Cabinet lighting lamp

- 16A socket outlet

- 220V 40A 4P terminal block

- 15-pole 20A control terminal block

- Incoming power phase indicator lamp

- Inductive loop detector

- PLC

- Weighing data acquisition and processing unit

- Switching device

- POE for lane camera

- POE for panoramic camera

- ODF optical distribution frame, 8 ports

- Thermostat and controller for the cabinet exhaust fan

Features

- Anomaly Alerts: Provides notifications when motion is detected or when incidents occur.

- Remote Control: Can be managed via a mobile app or computer.

- Security Features: Supports security measures such as video encryption and access protection

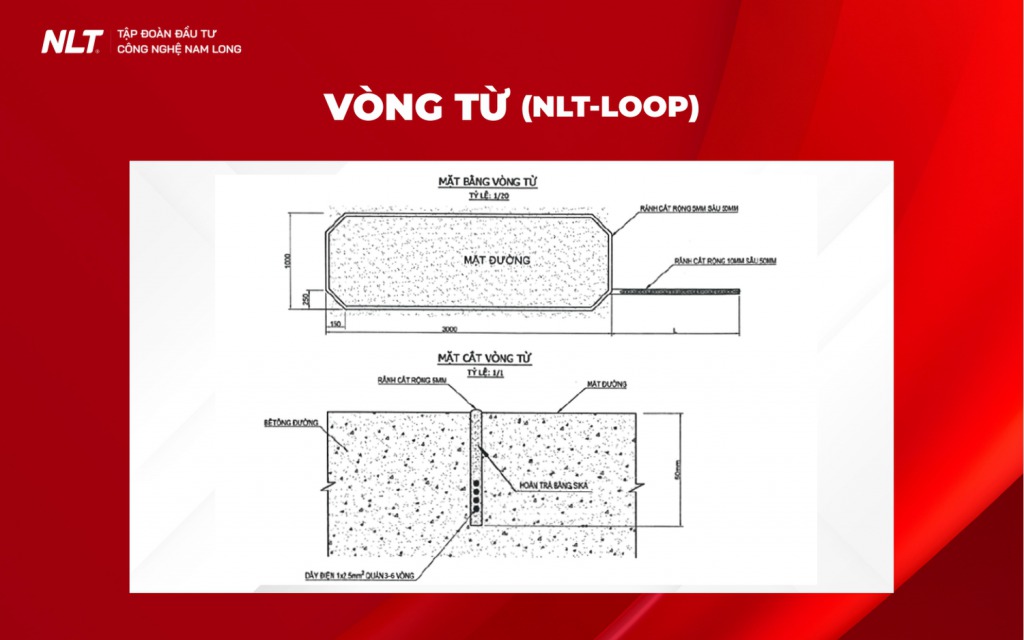

NLT Group’s inductive loop

- Made in Vietnam

- Dimensions: Xm x Ym (compatible with the weighing sensors)

- Number of turns: 3–6 turns

- Inductive loop wire: Cadivi cable, 2.5mm² cross-sectional area

- Manufactured using an NLT 14g loop installed on the road surface in front of the sensor bars. This loop is connected to the inductive loop detector installed in the control cabinet.

- Sika sealant is used to seal the loop installation grooves.

- Operating temperature: 0–80ºC

Contact NLT Group for solution and product consultation

NLT Group is a group that owns one of Vietnam’s leading multi-sector digital transformation ecosystems. Customers and businesses who need consultation on solution installation are welcome to contact NLT Group via the hotline 0911 379 581 for free consultation. We are committed to always accompanying and supporting our customers throughout the product lifecycle.

NLT Group

Nam Long Technology Investment Group (NLT Group)

Hotline: 0911 379 581 – 028 3535 5968.

Email: kinhdoanh@nlt-group.com.

Tax code: 0313339640.

Address: 43T Ho Van Hue, Đuc Nhuan Ward, Ho Chi Minh City.

-

Top 7 advantages of NLT Group’s smart vehicle weighing system

Tiếng Việt

Tiếng Việt